What is Laminar Air Flow – Principle, Diagram, Uses, and Types

In cleanroom technology, pharmaceuticals, electronics manufacturing, and research laboratories, maintaining a contaminant-free environment is crucial. One of the most effective methods to achieve this is through Laminar Air Flow (LAF) systems. These systems ensure a continuous, uniform flow of air that minimizes contamination and maintains sterile conditions. But what exactly is Laminar Air Flow, and how does it work? Let’s break it down.

What is Laminar Air Flow?

Laminar Air Flow refers to the airflow in which air moves uniformly in parallel layers, with minimal turbulence. Unlike turbulent airflow, which mixes air particles in multiple directions, laminar flow ensures that clean air moves in a single direction at a constant speed. This type of flow is essential in environments where maintaining cleanliness and minimizing particle presence is critical.

Laminar Air Flow systems are commonly used in biological safety cabinets, cleanrooms, and sterile production areas where any particulate contamination can compromise the product or process.

Principle of Laminar Air Flow

The principle of Laminar Air Flow is based on streamline movement of filtered air through HEPA (High-Efficiency Particulate Air) or ULPA (Ultra-Low Penetration Air) filters. These filters remove contaminants such as dust, bacteria, and other airborne particles.

Once filtered, the air moves in straight, parallel paths at a uniform velocity. This stream of clean air sweeps away any contaminants from the work surface or sterile zone, directing them away toward exhaust vents or return filters. Because of this controlled, unidirectional flow, the risk of cross-contamination is drastically reduced.

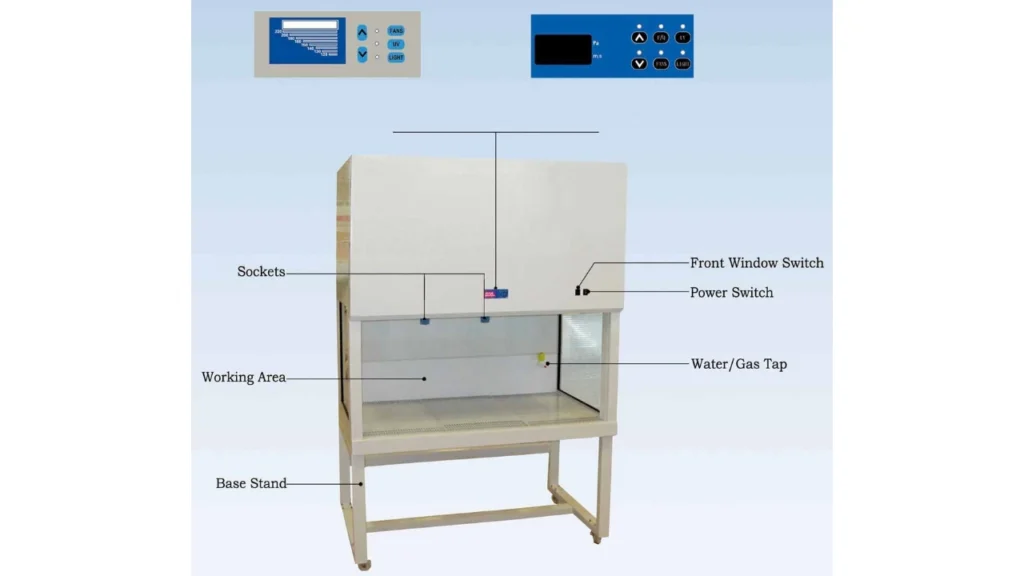

Diagram of Laminar Air Flow

Here’s a simplified representation of how a Laminar Air Flow unit operates:

-

HEPA Filter: Positioned at the top or back, depending on the design.

-

Uniform Air Flow: Moves in one direction, either vertically or horizontally.

-

Work Surface: A sterile area where materials or components are handled.

-

Pre-Filters: Capture larger particles before air reaches the HEPA filter.

Uses of Laminar Air Flow

Laminar Air Flow systems have diverse applications across various sectors, including:

-

Pharmaceuticals: In drug formulation and compounding to maintain sterility.

-

Hospitals & Laboratories: During surgeries, specimen preparation, and culturing microorganisms.

-

Electronics Manufacturing: For assembling semiconductors and circuit boards, where dust can affect performance.

-

Food Industry: To package products in sterile environments.

-

Research & Development: In cleanrooms and biosafety cabinets.

Types of Laminar Air Flow

Laminar Air Flow systems are generally classified based on the direction of airflow:

-

Horizontal Laminar Flow

-

Air Flow Direction: From the back of the unit toward the operator.

-

Best For: Applications where vertical airflow might disturb sensitive materials.

-

Consideration: The air passes over the operator, increasing the chance of contamination in some cases.

-

-

Vertical Laminar Flow

-

Air Flow Direction: From top to bottom, over the work surface.

-

Best For: Highly sterile processes like in pharmaceutical production.

-

Consideration: Requires proper placement of materials to prevent airflow obstruction.

-

Conclusion

Laminar Air Flow systems are vital in environments requiring high levels of cleanliness and contamination control. By using advanced filtration and controlled airflow, these systems ensure that operations in labs, manufacturing, and healthcare settings meet strict hygiene standards.

At PerfectAirCon, we specialize in providing advanced air filtration and climate control solutions, including custom Laminar Air Flow systems. Contact us today to learn how we can help you design a contamination-free workspace tailored to your industry needs.

Comments

Post a Comment